Proudly Working Alongside

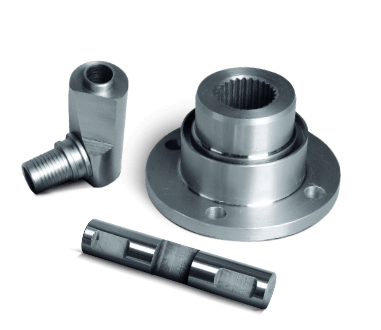

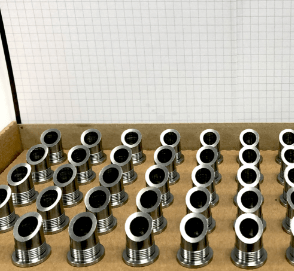

At MAS Precision Engineering, we pride ourselves on complete accuracy and precision; which is why we use only the finest CNC turning & machining equipment available today. Through our commitment to this and the capacity of our 13,000ft² facility, we will invest in new machinery as required by our customers - either to complete complex parts or achieve time-critical requirements.

MAS Precision Engineering is a family-run business started by two brothers, Martin and Steve. They both share a passion for British engineering and are lifelong precision engineers with a dedication to detail.

Managing Director

Works Director

Engineering Manager

Martin and Steve launched MAS Precision Engineering in the height of the recession with a single CNC machine and a small client base. Through a strategic business plan, recognition of their capabilities and outstanding customer retention, the business has grown rapidly to become a market leader in precision machined parts.

During the dark days of 2010, Martin and Steve launched MAS Precision Engineering Ltd.

Major order awarded for JLR Components.

July

New STAR Sliding-Head purchase/ Apprentice programme started.

August

New work awarded sees turnover increase by 30%!

December

Purchase of new Wickman Machine to cope with demand.

March

Moved into new premises at Atherstone, Warwickshire.

December

Awarded ISO 9001:2015 accreditation. Developed first overseas order.

June - September

Order of a Star SR-32J CNC lathe and new bending machine. New office development completed.

January - July

New starters, Reece and Darren joined MaS. Installation of new machinery with training from Star GB.

January - December

Continue to develop opportunities overseas and expand capacity with additional Star CNC machine.

April

In April 2020, we reached our 10th birthday. We had hoped for some celebrations, however - we never expected that our 10th anniversary would be celebrated in lockdown!

Lockdown

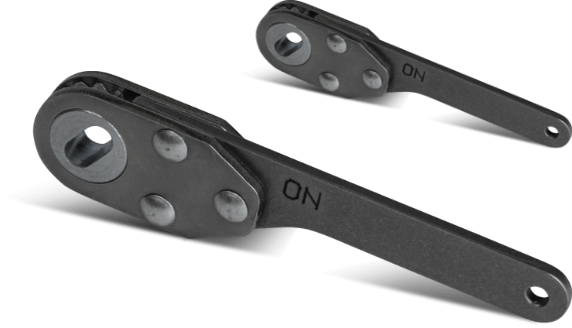

During the 2020 lockdown, we were approached to manufacture ratchet spanners for Oxygen Cylinders for the NHS. The use of oxygen was significant during the pandemic and the whole team at MaS are proud to have helped the NHS during the pandemic.

August

In August of 2020, Tracey celebrated 10 years' service at MaS. Tracey wears many hats, but essentially, works in our inspection and packing departments. Tracey is a loyal and valued member of our team. Well done Tracey!

Jan

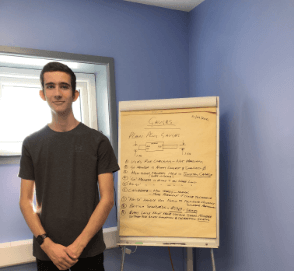

In January we welcomed Dan Newton to our team as our new apprentice. The whole MaS team wish Dan the very best during his career at MaS.

April

In April 2021, As part of our maintenance replacement program, we upgraded one of our Wickman machines. These machines produce high-quality-high-volume machined parts at very competitive prices, making it the perfect addition to our lineup.

May

In Spring 2021 we gained new overseas business supplying specialist automotive parts to a client based in Thailand.